Treating wood to protect it can make it a long lasting and very durable material. Wrong treatment in the wrong conditions can make it lasting less. For example if you put a plastic color on the facade of the building that is normally more harming then helping.

what to archive

If you want to treat wood you normally have two reasons:

- you want to make it waterproof or repellent or less prone to sucking moisture

- you want to prevent mold (mushrooms), bacteria or insects harming the wood (biocidal protection: insecticidal, fungicidal, bactericidal)

Depending on the use of the wood you want one of these or both. For example if you want a cutting board you want to make it waterproof or repellent. But normally you do not need any biocidal protection.

On the other hand if you have a roof construction in some areas you want biocidal protection but you do not need any protection against water.

A case where you want full protection is for example a wooden roof. On top it needs to be waterproof and on the bottom it is good to have a biocidale protection. Also wood which touches the earth often needs both.

Then there are other demands, for example a wooden roof needs to have a flexible and sturdy water protection. A cutting board also needs a good treatment as you do not just want to cut through your protective layer. In general if you treat wood in a way preventing moisture getting in or out you need a sturdy and flexible protection. When small parts are not protected anymore moisture can enter easily there but vaporizes extremely slow out again (because most of the wood is covered).

And this last point is a big problem with the common plastic colors for buildings. Because the wood works a lot because of fluctuating temperatures and humidity you soon get small cracks in these kind of coatings. Moisture can enter there when the rain comes from the side but because most of the wood is covered it dries very badly, even if it had air movement in the back. It is often difficult to get these paintings off again. In these cases it is better to leave the wood unprotected.

wood treatment you can buy

A lot of shops have a huge selection of wood treatment stuff you can buy. Normally they do not tell you at all what is in there. Basically they consist of three product groups:

cheap stuff

The cheap stuff were you get a canister for 10€ is mostly mainly water with some added color and perhaps some traces of oil. This stuff is in the best case useless and in the worst case it harms.

oil based

Oil based products contain a vegetable oil which oxidizes over time. The iodine number of oils tells you how fast and complete an oil is oxidizing. The higher the number is the better it oxidizes. Manufactors basically never tell you in detail what is in there. These products are normally two expensive compared to buying pure oil. Often they are stretched with cheaper ingredients.

plastic based

Plastic based products normally consist of some kind of polymer which closes the surface of the wood. They are similar to one component glues. Here you also never really know what you get and what characteristics the stuff has. If you want something which is decent in quality you need to pay quite a lot.

highest quality wood treatment

If you want the highest quality you do not need to pay anything extra, but you need to buy pure ingredients and think about what you want to archive.

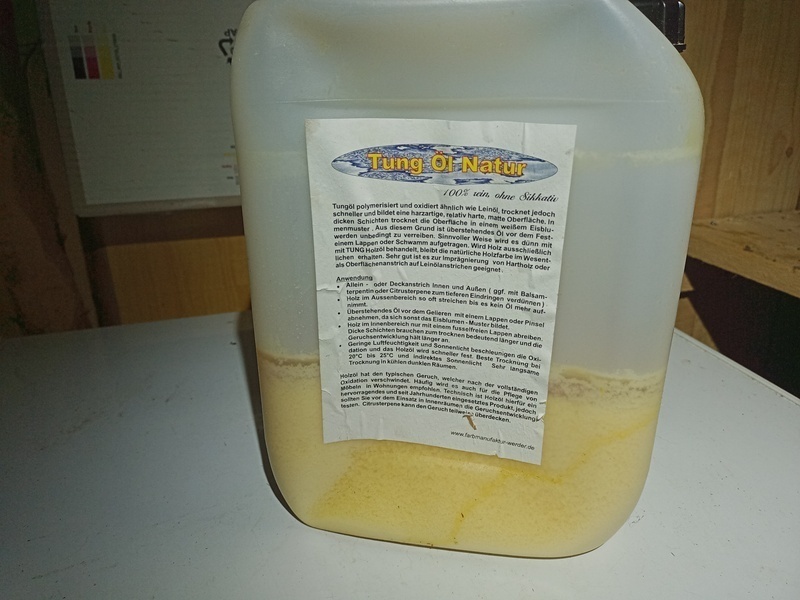

oil penetrative protection: Tung oil (protection against water)

Tung oil is the oil with the highest iodine number. You get a liter for about 10€ if you buy it from importers directly. It oxidizes highly producing a good protective layer. Depending on cold or hot pressed versions it oxidizes faster or slower. It works much better then linseed oil. Temperature and humidity are also important factors for the reaction.

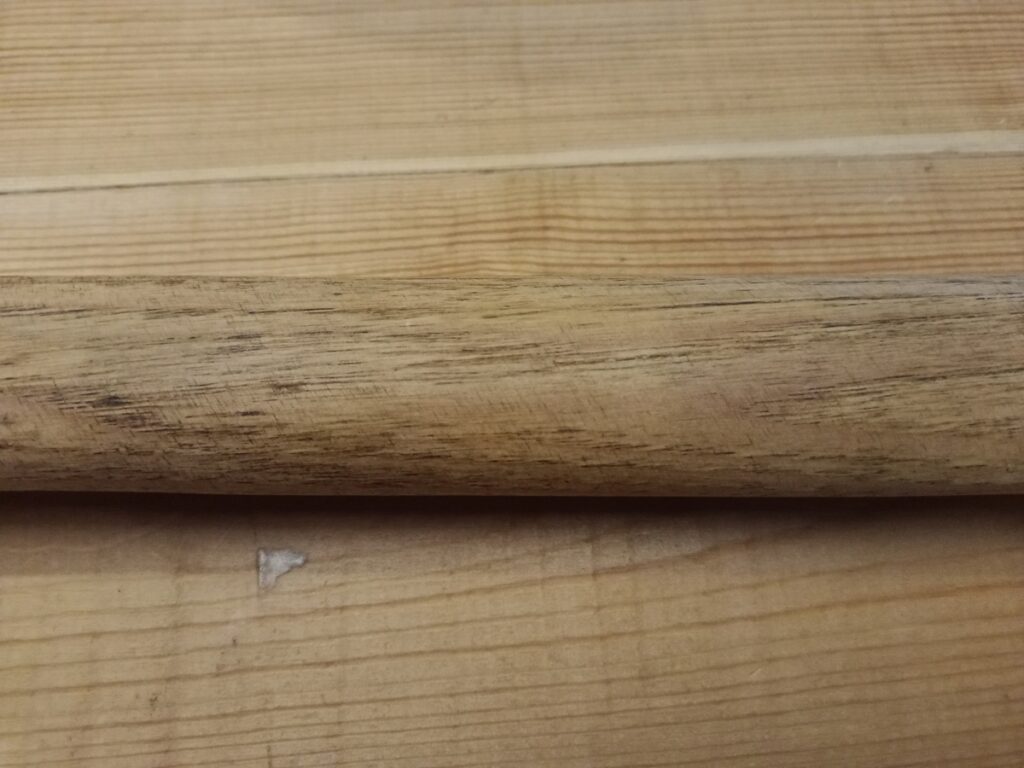

The amount you need for a surface is pretty low, starting from 100ml/m² up to 400ml/m² for pine/spruce wood. It is not producing a visible layer. So the wood mainly still looks like wood, just getting a little bit darker. It penetrates the wood and goes a little bit in, so scratches and other damages of the surface normally do not harm the protection too much. It is perfect for wooden floors if you take care that there is no standing water on them.

You often read that the wood can still breathe through the oil finish. But physically that is basically impossible. So you should count an oil treated surface as not breathable.

You should not make too thick layers and should use a cloth to spread it. If there is a standing layer of oil on the wood surface it polymerizes slower and it can produce unpleasant surfaces.

Tung oil makes some physical properties of wood better! The surfaces get more resistant.

Tung oil is not so expensive and you can get it in the EU for 10€/l.

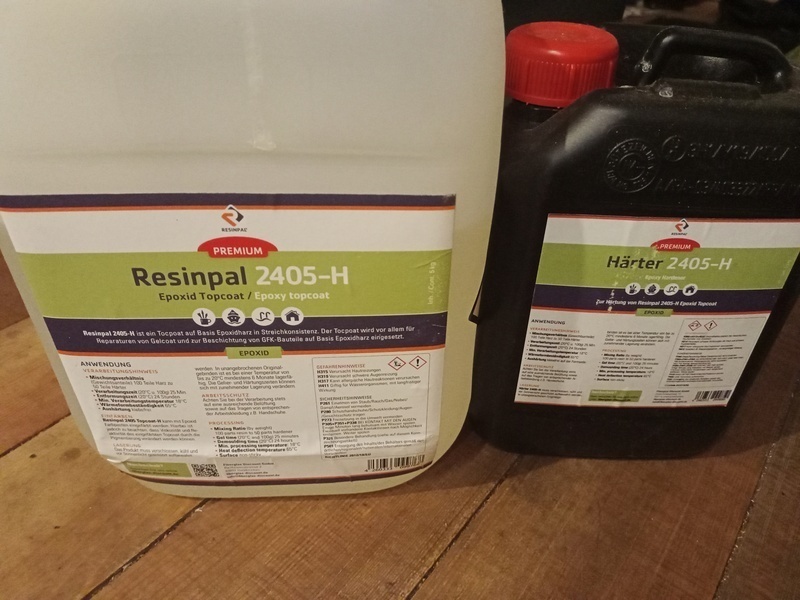

plastic based protection: 2k-epoxy (protection against water)

2k-epoxy is perfect for a closed finish wood treatment. The surface gets absolutely watertight and on the same time the epoxy is very flexible so it doesn’t brake easily even if the wood is working. Epoxy is very tough and bounds strongly to the wood. The wood fiber itself is less bonding together then the epoxy on the wood. It doesn’t peel off, is not so prone to UV aging and withstands the environment well.

There are a lot of different epoxies with higher or lower viscosity and other properties. Normally gel coats are good for a thicker and sturdy surface. When you use epoxy it is good to coat the wood on all sides that it can not work a lot any more. A good epoxy starts from 10€/kg. Take care on the ingredients, some crystallize when stored under 0°C and some can have a yellowish or blueish taint. Normally you need 20°C that it hardens. Some can harden slowly also at lower temperatures. You need about 200ml/m² to 1000ml/m² depending on the thickness of the layer.

Often one coating is enough. When you look at some higher quality ready mixtures of plastic based wood treatment you often need to apply it at least 3 times for a good surface. So even if you have some extra work with the mixing of epoxy you normally do not have more effort.

usage tips

It is better to spread it with a brush instead of something else. You need to stir it well, but then bubbles occur easily. Warm the epoxy in a water bath slightly and the bubble will go out fast. If you warm it too much the reaction goes to fast and your working time gets very short.

If you need to mix 1 part hardener and 2 parts resin then first pour the hardener. It is easier to make a bigger amount precise. For example if you want 60g mixture and you add the 20g hardener first and make it 1g wrong then it is easier to compensate with the resin as it equals 2g.

If you have bubbles on the surface and the epoxy is still liquid you can warm it up carefully with a hairdryer. This will help that the viscosity lowers and the bubbles go out. Be carefully not to blow the epoxy so move the hairdryer fast and far enough away from the surface.

warning

Unhardened epoxy resin is toxic! Most unhardened epoxy resins contain Bisphenol (often A or F) which are highly toxic. Do not get resin on the skin.

Important: Hold exactly to the instructions of the epoxy resin, use proper protection gloves (no one time use). The ratio of epoxy and hardener needs to be exact and temperature sufficient.

read more about epoxy:

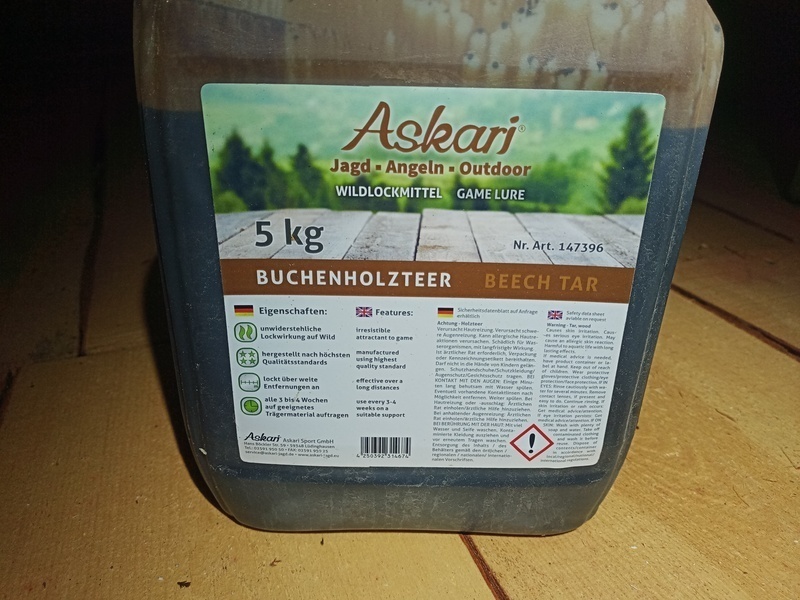

wood tar (biocidale protection)

Wood tar, for example beech or pine tar, is a condensate out of wood containing different lighter substances then the wood itself. In nature it serves as a protection for the tree and is mainly visible as resin at the bark. Different tree species produce different kinds. Beech tar is the most effective in Europe and something similar was used for over 100 years for the wood of the railways.

Wood tar is not hardening, polymerizing or oxidizing. It stays very liquid. Lighter substances vaporize over time. That’s why wood treated with it smells burned for a longer time and you can use it only outside. Because it stays more liquid it penetrates the wood deeply over the years. The advantage is that damages do not harm the protection. The disadvantage is that more and more tar is getting from the outside to the inside (where it is not needed so much). Water washes the tar slowly out.

If you make a wooden roof you should first apply the tar and in the second year make an oil or epoxy layer.

For applying you should warm the tar up that the viscosity gets lower. Then you can use a brush to spread it. I normally use a camping gas stove and a pot with tar and the gas stove stays on on a lower level. Wood tar burns, so you need to take a little bit care. Some people add thinner for applying and lowering the viscosity. But thinner is normally more expensive then wood tar and is otherwise not helping.

Wood which is protected properly with tar can be even in the earth and rots very slowly.

The amount you need depends highly on how often you apply it, how thick and what wood you treat.

Wood tar is highly fungicidal, bactericidal and insecticidal because it contains creosote. But creosote makes it also toxic.

It is a traditional way of protecting fence posts and also a traditional method of treating wooden boats is by a mixture of pine tar and linseed oil. It is a by-product in the wood coal producing and therefore extremely cheap. You often get 1kg beech tar for 2€.

The commercial use of wood tar is forbidden in the European Union. Wood tar contains carcinogenic substances (that is why it is so efficient). Do not get it on the skin! Do not spread it on the ground!

verdict

I do not recommend the mixtures you can buy. It is much more worth to buy pure ingredients then some premixed stuff where you do not know what is in!

There are also other good wood treatments besides the three mentioned ones. But with these three you can normally find something suitable for every environment.